Zeynep Karatza

National Technical University of Athens, Greece

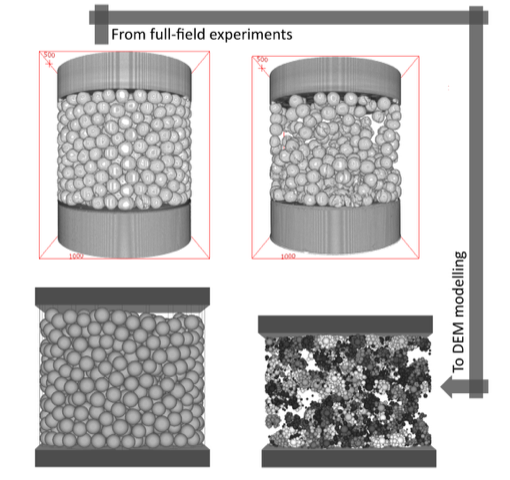

Despite the immense progress of numerical modelling, DEM models still rely on experimental data to provide constraints on material behaviour for the calibration of input parameters and validation of the simulation results. The main limitation of conventional experimental means is that the processes in action are rarely directly observed, and so, often, DEM practitioners resort to empirical curve fitting parameters/techniques that can usually only describe an average response of the simulated material. Since the deformation of a granular assembly is complex and heterogeneous, gathering quantitative full-field information (i.e. a field record of a quantity as opposed to a bulk measurement) is imperative, and has been an essential component of my research using predominantly x-ray computed micro-tomography (XCT). XCT has been growing in popularity in recent years as a research tool in material sciences and engineering. Its success lies in the fact it has enabled the observation and measurement in 3D of the deformation and kinematics of materials during loading. In my research I have focused on studying deformation mechanisms and particularly particle breakage. I developed bespoke loading apparatuses for XCT and algorithms that allowed for the first time to simultaneously track particles and their fragments to investigate how particle morphology and coordination number affect the different types of breakage. Interestingly, a significant amount of breakage was detected well before the typically defined yielding point, that is often associated with the onset of particle crushing. This information was used to develop a new DEM model, where breakage is simulated by particle replacement (used for primary splitting breakage) and clustering (used for breakage of fragments). The model was validated and calibrated using information from the experiments at multiple scales (particle and whole assembly) and both the particle size distributions and the stress-strain response obtained with the new DEM model matched the experimental results.